Steel cord conveyor belt

Steel cord conveyor belts are suitable for conveying materials such as coal, ore, cement, and grain.

Belt Width: 800–2400 mm

Thickness: 18–50 mm

Wire Core Diameter: 3–6 mm

Number of Wire Core Layers: 1–4

Operating Speed: 2–6 m/s

What is steel cord conveyor belt?

Steel cord conveyor belts are high-strength, wear-resistant, and tear-resistant industrial conveying equipment. They are primarily constructed of a high-strength steel wire core and a rubber covering. They offer high load capacity, low elongation, and excellent impact resistance, making them particularly effective in conveying long distances, at steep angles, and under high loads.

-

Steel cord conveyor belts are suitable for conveying coal, ore, cement, chemicals, metal minerals, and granular or bulk materials. They have a wide operating temperature range, generally withstanding temperatures from -30°C to +100°C. High-temperature rubber belts can even handle hot materials below 700°C. Steel cord conveyor belts typically operate at speeds between 2 and 6 meters per second and can be customized to suit specific operating conditions. Conveyor lengths can range from a few hundred meters to several thousand meters, with maximum lengths exceeding 8 kilometers. Standard steel cord conveyor belts are suitable for slopes of 0–35°, while special anti-slip designs enable even steeper slopes. Depending on the specifications and performance requirements, prices generally range from US$5 to US$25 per meter, depending on the strength of the steel cord, the thickness of the rubber wear layer, and the degree of customization.

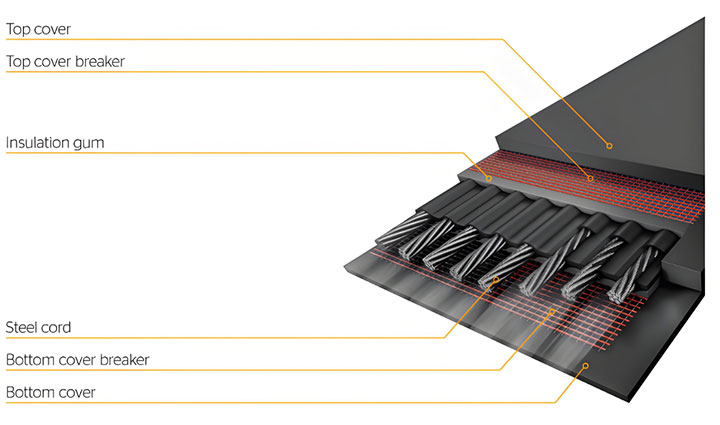

Steel Cord Conveyor Belt Structure

Steel cord conveyor belts utilize parallel, high-strength galvanized steel cords as their backbone, providing extremely high tensile strength and very low elongation. The steel cords are covered with a rubber layer: the upper rubber layer is wear-resistant and impact-resistant to withstand the wear and corrosion of large tonnage materials; the lower rubber layer is non-slip and wear-resistant, ensuring transmission friction and protecting the steel cord. Depending on the operating conditions, the rubber layer can be designed to be resistant to high temperatures, oil, or cold weather, significantly extending the belt's service life.

How does steel cord conveyor belt work?

Steel cord conveyor belts utilize friction from the drive drum to circulate, enabling continuous material conveying. Material falls from the feed opening onto the belt surface. The high-strength steel wire core, with its extremely low elongation and ultra-high tensile strength, ensures the belt remains tight and stable even under heavy loads, at high speeds, and over long distances, preventing slack or material spillage. A tensioning device regulates overall tension, ensuring smooth and safe operation. When conveying at steep angles, anti-slip rubber or baffles can be used to effectively increase friction and prevent material slippage, improving conveying efficiency and adaptability.

Steel cord conveyor belt specifications

| ST Rating | Recomm-ended Cord Dia (mm) | Pitch (mm) ±1.5 | Belt Width | Minimum Recommended Pulley Diameters (mm) for MAWT utilisation > 60% | |||||||||||||

| 800 | 900 | 1000 | 1050 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | A | B | C | |||

| 500 | 2.6 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 560 | 2.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 630 | 2.9 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 710 | 3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 800 | 3.1 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 900 | 3.3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1000 | 3.5 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1120 | 3.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 164 | 800 | 630 | 500 |

| 1250 | 4.2 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1400 | 4.5 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1600 | 5 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 1800 | 5.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2000 | 6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2250 | 6.2 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2500 | 6.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 2800 | 7 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3150 | 7.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3550 | 8 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4000 | 8.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4500 | 9.2 | 16 | 46 | 52 | 59 | 65 | 71 | 84 | 90 | 96 | 109 | 121 | 134 | 146 | 1400 | 1250 | 1000 |

| 5000 | 10.4 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 5400 | 11 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 6300 | 11.6 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 2000 | 1800 | 1600 |

Standard Steel Cord Range (AS 1333)

| ST Rating | Recomm-ended Cord Dia (mm) | Pitch (mm) ±1.5 | Belt Width | Minimum Recommended Pulley Diameters (mm) for MAWT utilisation > 60% | |||||||||||||

| 800 | 900 | 1000 | 1050 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | A | B | C | |||

| 500 | 2.6 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 560 | 2.8 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 630 | 3 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 500 | 400 | 315 |

| 710 | 3.1 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 630 | 500 | 400 |

| 800 | 3.3 | 13.8 | 56 | 63 | 70 | 74 | 84 | 99 | 106 | 113 | 128 | 142 | 156 | 170 | 800 | 630 | 500 |

| 900 | 3.8 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1000 | 4 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1120 | 4.3 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1250 | 4.5 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 800 | 630 | 500 |

| 1400 | 4.8 | 15.3 | 50 | 56 | 63 | 66 | 76 | 89 | 96 | 102 | 115 | 128 | 141 | 154 | 1000 | 800 | 630 |

| 1600 | 5.5 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 1800 | 5.9 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 2000 | 6.4 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1000 | 800 | 630 |

| 2250 | 6.8 | 17.3 | 45 | 50 | 56 | 59 | 67 | 79 | 85 | 90 | 102 | 113 | 124 | 136 | 1250 | 1000 | 800 |

| 2500 | 7.4 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1250 | 1000 | 800 |

| 2800 | 8 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 3150 | 8.6 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 3550 | 9.2 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1400 | 1250 | 1000 |

| 4000 | 9.8 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1400 | 1250 |

| 4500 | 10.4 | 19.4 | 40 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1250 | 1000 |

| 5000 | 11 | 19.4 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 1600 | 1250 | 1000 | |

| 5600 | 11.8 | 19.4 | 45 | 50 | 52 | 60 | 70 | 75 | 81 | 91 | 101 | 111 | 121 | 2000 | 1800 | 1600 | |

| 6300 | 12.8 | 20 | 43 | 48 | 50 | 58 | 68 | 73 | 78 | 88 | 98 | 108 | 118 | 2000 | 1800 | 1600 |

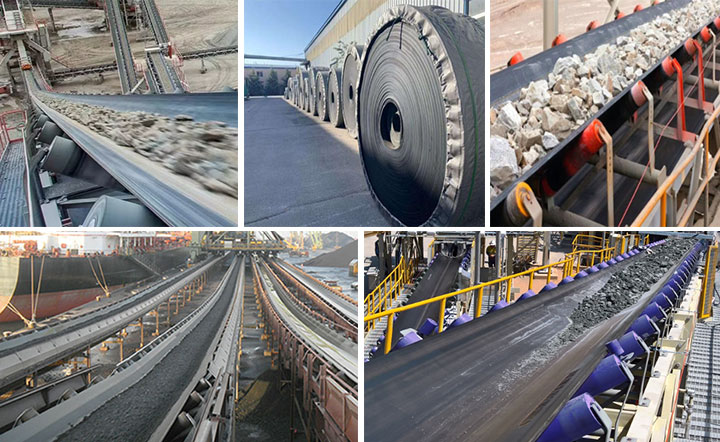

Steel cord conveyor belt industry applications

Steel cord conveyor belts are widely used in industries such as mining, coal mining, power generation, cement, steel, and chemicals. In the mining industry, they are primarily used for long-distance conveying of materials such as iron ore, copper ore, coal, and sand and gravel, and are particularly well-suited for high-intensity, high-load, continuous transport. In the power industry, they are used for coal transportation and ash handling. In the cement and steel industries, steel cord conveyor belts are used for material conveying and finished product transport, ensuring continuous and efficient production processes. In the chemical industry, they can transport granular chemical raw materials and mineral powders, while corrosion-resistant rubber layers can be selected as needed to extend service life. Steel cord conveyor belts are also used in ports, terminals, and logistics conveyor systems to facilitate the rapid loading and unloading of bulk materials.

Steel cord conveyor belt case study

The main inclined shaft conveyor system of an open-pit coal mine originally used ordinary steel cord conveyor belts, which caused frequent shutdowns due to longitudinal tears and joint failures. After being replaced with a specially designed tear-resistant steel cord conveyor belt, the belt body, with high-tensile steel cord as the skeleton and covered with ultra-wear-resistant rubber, solved the problems of easy tearing and short life of traditional fabric belts. It operated stably for 36 months under conditions of 3.5 kilometers and a 16-degree slope, with the failure rate reduced by 80%.

Steel Cord Conveyor Belt Price

The price of steel cord conveyor belts is influenced by many factors, including the wire core specification, rubber layer thickness, wear and temperature resistance, and custom lengths. Standard models generally cost between $5 and $25 per meter. Customized models with high strength, high temperature resistance, or corrosion resistance can cost upwards of $30 per meter. When purchasing, consider belt width, conveying length, and material characteristics to select the best value. Long-term maintenance costs are also a key factor in evaluating overall economics. Reliable quality and long life products significantly reduce downtime and replacement costs over time.

Steel Cord Conveyor Belt Suppliers

Among steel cord conveyor belt suppliers, our factory has many years of experience in manufacturing industrial conveying equipment. The company's steel cord conveyor belt manufacturing features the following: High-quality carbon steel and precision machining ensure high load-bearing capacity and long service life for the steel cord core. We offer a variety of rubber formulations, including those resistant to wear, high temperatures, oil, and corrosion, tailored to the needs of the mining, coal, power, and chemical industries. This ensures a tight bond between the steel cord and the rubber layer, preventing delamination during operation and improving conveyor belt safety.